Modelling cement mixtures with SCMs

The reactivity of a SCM is defined as the maximum amount of the SCM that is capable in participating in the chemical reactions – crystalline components generally do not react in cementitious systems (Glosser et al., 2021). As an alternative to assuming full reactivity of the SCM (e.g. in Tutorial Calculate the cement hydrates assemblages with part of OPC is replaced by GBSF), it can be assumed that only part of the SCM is reactive. Following the approaches proposed by Glosser et al. (2021) for fly-ash, the alternatives are for the case where the SCM composition is defined in terms of bulk content of oxides:

• An overall reactivity is defined; each oxide content is multiplied with the reactivity.

• An oxide-specific reactivity

Methods for obtaining the overall of the oxide-specific reactivity of fly-ash is given in Glosser et al. (2021).

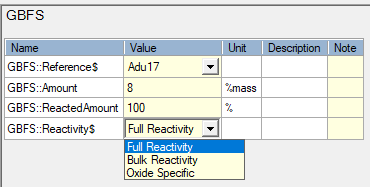

For each SCM in the ModuleCement_Input_02_Recipe tab, the type of reactivity of the SCM is specified via the drop down menu SCM::Reactivity (SCM is e.g. GBFS, FA, …) - (see Figure below):

- Option “Full Reactivity” – assuming 100% reactivity of all oxides.

- Option “Bulk Reactivity” – assuming the same reactivity of all oxides. The reactivity is defined in data blocks with the oxide composition of the SCM in the column Rtot (e.g., in the data block GBFS, similar for the other SCMs).

- Option “Oxide Specific” – assuming an oxide-specific reactivity. The reactivity is defined in data blocks with the oxide composition of the SCM in the columns Roxide (oxide = CaO, SiO2, …) (e.g., in the data block GBFS, similar for the other SCMs).

Note that the variable SCM::ReactedAmount parameter …expressed in %.